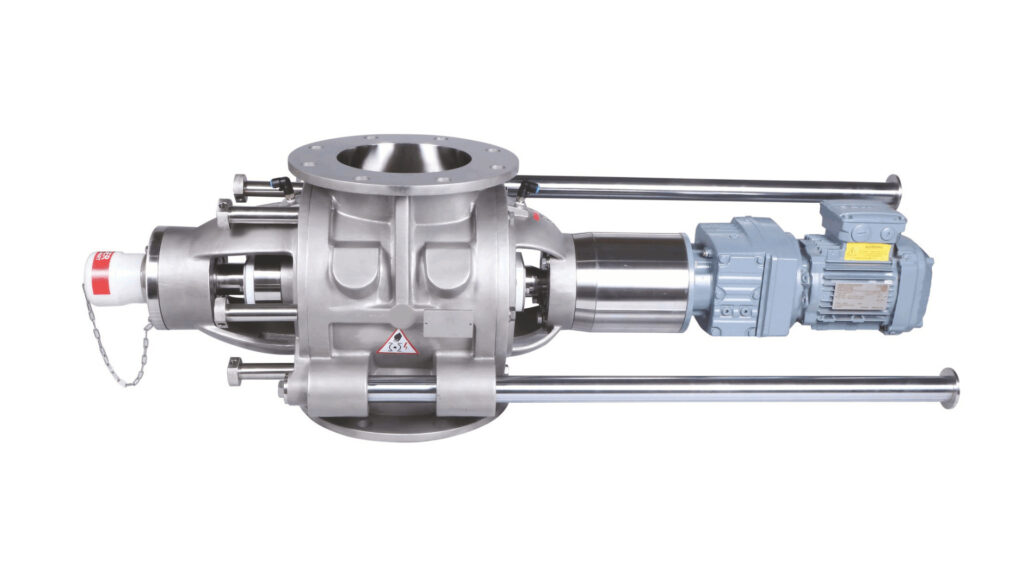

H-AR airlock

TBMA high-duty H-AR drop-through rotary valves are used for dosing powder and granular materials in 24/7 industrial processes. The H-AR valves can be used as a protective system up to 10 barg for products in dust class St1 and St2.

In combination with a blow-through or venturi adapter, the H-AR is very suitable for absorbing differential pressure in pneumatic conveying systems. The optimally constructed inlet of the valve ensures a high filling degree and large capacity with minimal air leakage.

Key Benefits:

- Dosing of powder and granular materials

- Absorbing differential pressure due to minimal air leakage

- Protective system up 10 barg for products in dust class St1 and St2 (optional)

- Suitable for 24/7 industrial applications

- Outboard bearings, dust tight and sealed for life

- Differential pressure 1,5 barg

- ATEX 2014/34/EU certified (optional)

- Sanitary execution conforming to EHEDG guidelines for dairy and food industry (optional)

Applications of the H-AR airlock

- High-duty drop through rotary valve

- 24/7 industrial applications

- Absorbing differential pressure

- Protective system up to 10 barg ( St1 and St2)

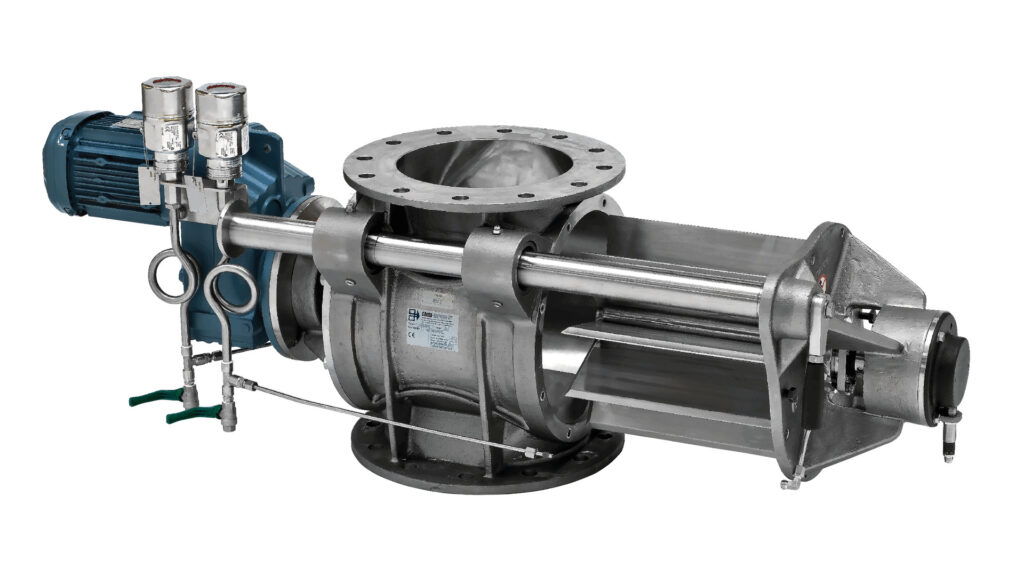

H-GR Blowing seal

TBMA high-duty H-GR blow-through rotary valves are equal to the H-AR valves and are used for direct dosing into pneumatic conveying systems in demanding, industrial applications.

The H-GR valves are equipped with connecting flanges for direct mounting to the pneumatic conveying lines on both the transport inlet as well as the transport outlet. The integrated blow-through connections are adapted to the rotor shape, ensuring that the rotor pockets are completely blown empty. The valves are also standard provided with vent holes.

Key Benefits:

- Dosing of powder and granular materials

- Absorbing differential pressure due to minimal air leakage

- Protective system up 10 barg for products in dust class St1 and St2 (optional)

- Suitable for 24/7 industrial applications

- Outboard bearings, dust tight and sealed for life

- Differential pressure 1,5 barg

- ATEX 2014/34/EU certified (optional)

- Sanitary execution conforming to EHEDG guidelines for dairy and food industry (optional)

Applications of the H-GR Blowing seal

- High-duty blow through rotary valve

- 24/7 industrial applications

- Absorbing differential pressure

- Protective system up to 10 barg ( St1 and St2)

DCSR-2T Rail valve

The DCSR-2T USDA Dairy Accepted and EHEDG compliant slide rail rotary valves are the perfect fit for any sanitary application where prevention of product contamination is top of the list. The valves are available in drop through (DT) or blow through (BT) version and are equipped with a tapered rotor and body. This design ensures that at no point the rotor and body will come into contact while opening or closing the valve. Also, when extracted the rotor can be smoothly rotated for easy cleaning.

The clearances of the rotor are prefixed during manufacturing, so no special tools or techniques are needed for the clearance settings.

The DCSR-2T valves are supplied in stainless steel 316 and are standard equipped with an 8 bladed rotor with radiused u-shaped pockets. All product contact surfaces are standard polished to 0,8 µm, optional up to 0,4 µm.

Key Benefits:

- Dosing of powder and granular materials

- Absorbing differential pressure due to minimal air leakage

- Protective system up 10 barg for products in dust class St1 and St2 (optional)

- Suitable for 24/7 industrial applications

- Outboard bearings, dust tight and sealed for life

- Differential pressure 1,5 barg

- ATEX 2014/34/EU certified (optional)

- Sanitary execution conforming to EHEDG guidelines for dairy and food industry (optional)

Applications of the DCSR-2T Rail valve

- Sanitary rotary valve

- 24/7 industrial applications

- Frequent cleaning and inspection

- Drop through ( DT) or blow through (BT) version

- Protective system up to 3 barg ( St1 and St2)

DG- QUICK CLEAN VALVE

TBMA DG Quick-Clean drop-through and blow- through rotary valves are specially designed for processes where frequent cleaning and inspection are required. The self-seeking spline shaft allows quick and easy remounting of the rotor after cleaning. Thanks to the clearance-free suspension and fixed adjustment, damage to the rotor tips and/or inside of the valve during (dis)assembly is limited to a minimum. In addition, the shaft seal cannot be damaged, since the spindle with spline remains in place when the rotor is pulled out.

Key Benefits:

- Suitable for frequent cleaning and inspection

- Self-seeking spline axis for quick (dis)assembly

- Absorbing differential pressure due to minimal air leakage

- Suitable for 24/7 industrial applications

- Outboard bearings, dust tight and sealed for life

- Differential pressure 1,5 barg

- ATEX 2014/34/EU certified (optional)

- Sanitary execution conforming to EHEDG guidelines for dairy and food industry (optional)

Applications of the DG- QUICK CLEAN VALVE

- High-duty rotary valve

- 24/7 industrial applications

- Frequent cleaning and inspection

- Protective system up to 10 barg ( St1 and St2)

H-AX Airlock

TBMA high-duty H-AX drop-through rotary valves are equal to the H-AR valves and are used when the inlet size is more important than the rotor volume. The relatively large inlet ensures that even the most poorly flowing products are efficiently discharged.

The H-AX valves are equipped with a round and a square connecting flange. This allows the valve to be used as a transition piece from round to square or vice versa. This is favourable for the installation height and saves any mounting parts.

Key Benefits:

- Dosing of powder and granular materials

- Absorbing differential pressure due to minimal air leakage

- Suitable for 24/7 industrial applications

- Relatively large inlet for products with poor flowability

- Outboard bearings, dust tight and sealed for life

- Differential pressure 1,5 barg

- Suitable as transition piece from round to square of vice versa

- ATEX 2014/34/EU certified (optional)

Applications of the H-AX Airlock

- High-duty drop through rotary valve

- Relatively large inlet for products with poor flowability

- Absorbing differential pressure

- Explosion proof up to 2 barg

S–AX Dust Valve

TBMA S-AX dust valves are specially designed to be used under dust filters and cyclones. Applications with a differential pressure up to 500 mbar where the valve primarily functions as an airlock or explosion barrier. The S-AX can be used as a protective system up to 2,5 barg for products in dust class St1 and St2. (optional).

These airlocks are made from GN40 nodular cast iron. This type of cast iron material is stronger and much less brittle than conventional cast iron, making it more resistant to shock loads, and has a high corrosion resistance. The installation weight of the S-AX is only 65 kg. The result is a particularly favourable price/quality ratio of this type of valves.

The S-AX valves are equipped with a round and a square connecting flange. This allows the valve to be used as a transition piece from round to square and vice versa.

Key Benefits:

- Light and compact dust valve

- For differential pressure up to 500 mbarg and easy to process products

- Body and covers made from high-tech GN40 nodular cast iron

- Outboard bearing, dust-tight and sealed for life

- Protective system up to 2,5 barg for products in dust class St1 and St2 (optional)

- ATEX 2014/34/EU certified (optional)

Applications of the DCSR-2T Rail valve

- Light and compact dust valve in GN40 nodular cast iron

- For differential pressure up to 500 mbarg and easy to process products

- Protective system up to 2,5 barg (St1 and St2)