DTD Plug Diverter

The DTD dual channel plug diverter valves are made of aluminium LM25 grade using a high-quality die casting process. All product contact surfaces are lined with 316 stainless steel tubes. FDA- approved silicone seals ensure complete sealing between the body and the plug. The standard diverter with static seals is suitable for systems up to 2 barg. With optional inflatable seals, it can handle pressures up to 6 barg. Supplied as a complete unit with pneumatic actuator, solenoid valve, coils, junction box, and position sensors.

Key Benefits:

- Dual channel plug

- Suitable for powders, granules, and pellets

- For diverting or converging

- Minimum product degradation

- Food grade silicone seals

- Stainless steel 316 contact surfaces

- Aluminium body, plug, and end covers

- No external moving parts

- Position indicators

- Air cylinder operated

- Easy maintenance

Applications of the DTD Plug Diverter

- For diverting or converging of powers and granules

- Suitable for pneumatic conveying systems

- Clever, value engineered design

SDTD Plug Diverter

The SDTD single channel plug diverter valves are made of aluminium LM25 grade using a high-quality die casting process. All product contact surfaces are lined with 316 stainless steel tubes. FDA- approved silicone seals ensure complete sealing between the body and the plug. The standard diverter with static seals is suitable for systems up to 1.5 barg. When equipped with inflatable seals (optional), the SDTD can handle higher pressures. It is supplied as a complete unit with pneumatic actuator, solenoid valve, coils, junction box, and position sensors.

Key Benefits:

- Single channel plug

- Suitable for powders, granules, and pellets

- Standard execution for diverting only

- Minimum product degradation

- Food grade silicone seals

- Stainless steel 316 contact surfaces

- Aluminium body, plug, and end covers

- No external moving parts

- Position indicators

- Pneumatic actuator operated

- Easy maintenance

Applications of the SDTD Plug Diverter

- For diverting or converging of powers and granules

- Suitable for pneumatic conveying systems

- Clever, value engineered design

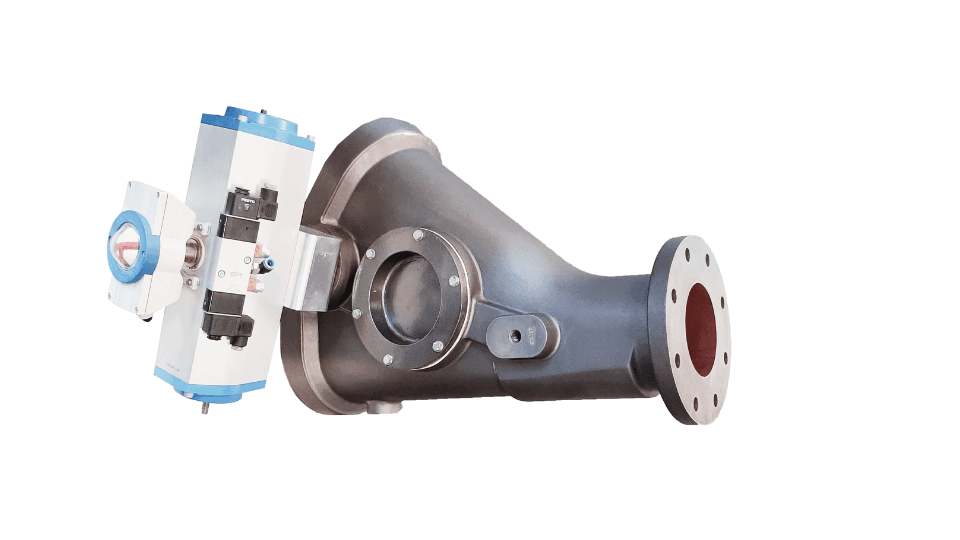

BTD Ball Type Diverter

The BTD ball type diverter valve is suitable for handling extremely abrasive products in heavy applications with relatively high line pressures and/or high temperatures. The diverter is made of ductile cast iron. The rugged design ensures that the higher the pressure, the better the seal works, as the ball and seal are pressed firmly into their seat. The seals can be replaced by removing the covers, meaning the BTD does not need to be dismantled or removed from the system. The BTD is controlled by a double-acting pneumatic cylinder with a 5/2 double-acting solenoid valve and a position switch.

Key Benefits:

- Suitable for extremely abrasive products

- Suitable for high line pressures and/or temperatures

- Rugged design

- Body made from ductile cast iron

- Interchangeable wear bushings on the flanges

- Grease lubricated shaft seals

- Seals can be replaced without removing the diverter from the system

- ATEX 2014/34/EU certified (optional)

Applications of the BTD Ball Type Diverter

- For diverting or converging of extremely abrasive products

- Rugged design of ductile cast iron

- Suitable for high line pressures and temperatures

RD Flap Diverter

TBMA type RD two-way flap diverter valves are suitable for transporting (mildly) abrasive, smooth-running powders or granules. These diverters are specially designed for diverting from 1 to 2 transport lines or vice versa with minimal pressure loss and good sealing properties.

Type RD diverters are suitable for simple two-way routing in pneumatic transport systems with an operating pressure up to 1 barg.

Control can be done either manually, with a pneumatic cylinder or with a pneumatic actuator assembly. The diverter valves are equipped with limit switches for indicating the open/closed position.

Key Benefits:

- Compact design

- Small change angle -22.5 °

- Low pressure loss due to smooth line transition

- Easy disassembly and maintenance

- In cast iron, stainless steel and aluminum

- Manual or electro-pneumatic control in closed box

- ATEX 2014/34/EU certified (optional)

Applications of the RD Flap Diverter

- For diverting or converging of extremely abrasive products

- Operating pressure up to 1 barg

- Minimal pressure loss

- Compact design

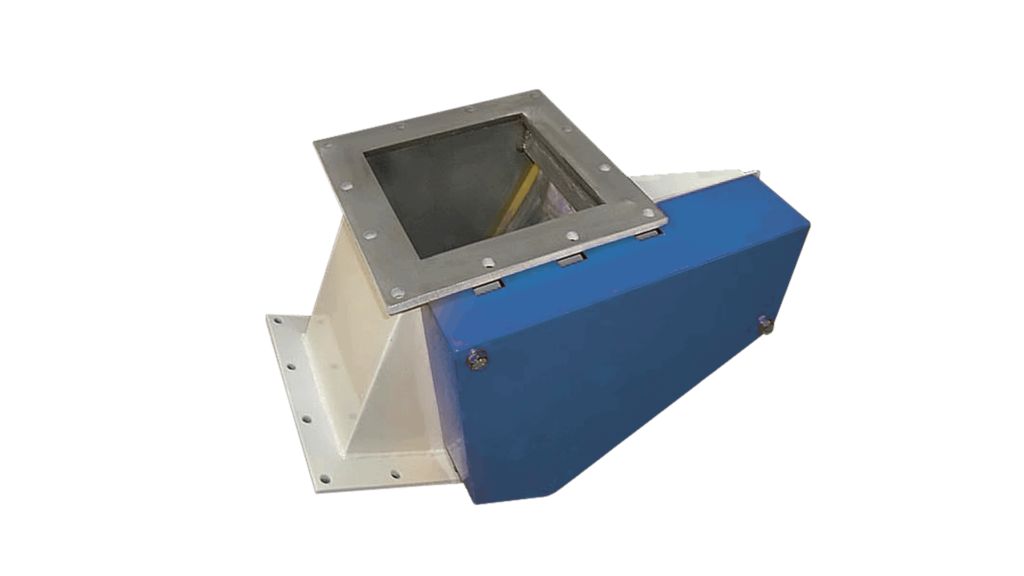

GFD GRAVITY DIVERTER

Free-fall gravity diverters are designed to divert powders and granules from one transport line to two or three others using gravity. The favourable change angle of 30° or 45° contributes to a fluent product flow and the smooth internal finish prevents product build-up.

The air cylinder is electro-pneumatically controlled by a 5/2-valve. The switch position is monitored by limit switches mounted to detect the open/closed position. The manual version is operated with a handle and is also provided with the before mentioned limit switches.

Key Benefits:

- Compact and robust construction made of mild steel

- Smooth line transition

- Easy disassembly and maintenance

- Various material versions

- Sealing flap made from polyurethane

- Manual or electro-pneumatic control in closed box with limit switches

Applications of the GFD Gravity Diverter

- Diverting only into two or three lines

- In and out round, square or rectangular

- For gravity applications only